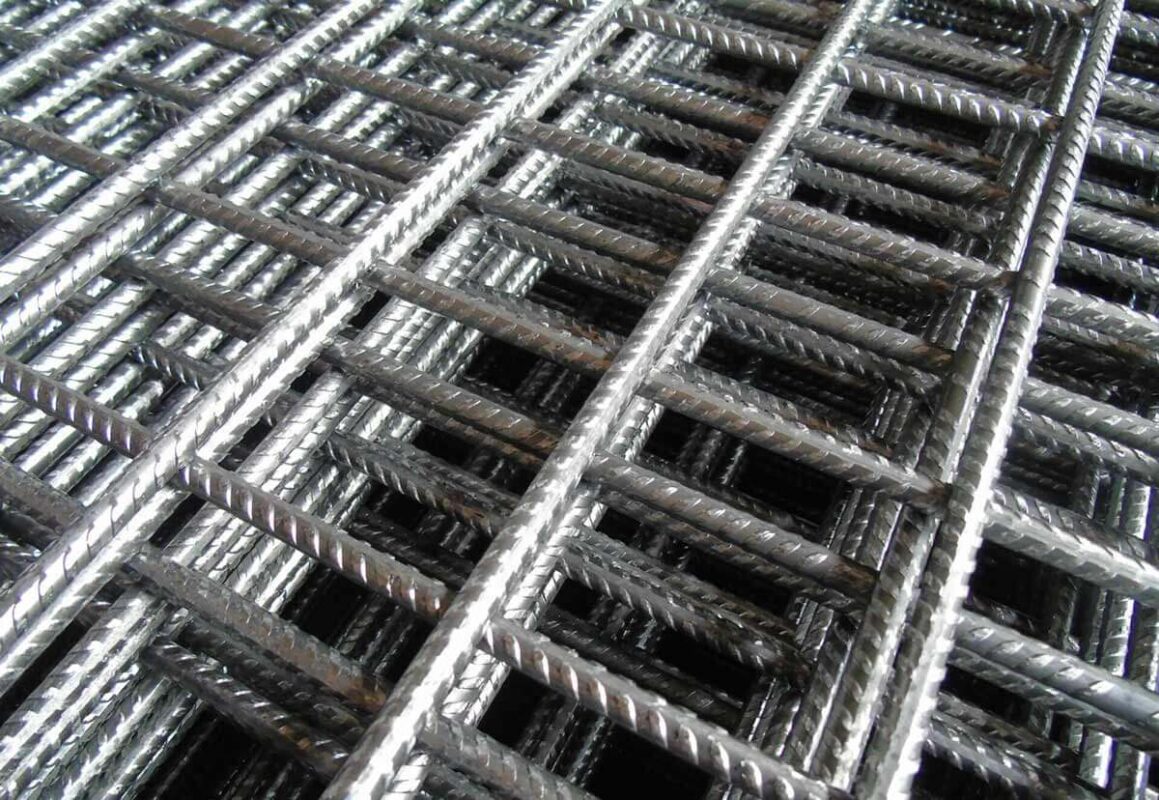

One of the materials utilized in the building sector is welded wire mesh. The mesh is a kind of wire netting that is constructed from steel bars. In actuality, the rebars are positioned on top of each other and joined longitudinally and transversely at a right angle. To ensure that the bars do not move, spot welding is used to join them at their intersection. Stay with us to the end if you want to learn more about this product and its applications.

What is Werlded Wire Mesh?

Mesh net, also known as welded net, is created by utilizing straightforward and ribbed bars. Of course, occasionally iron and galvanized wire are also employed as the primary components of this metal net. The finished result will take the shape of a steel grid, and the wires are essentially woven together to create this. In actuality, meshes made of wire have a aperture form that is distinct from meshes built of rebar. Wires are welded together to create this product, which obviously requires a unique procedure.

Additionally, this product has numerous uses in the building sector because it exhibits greater resistance than wire. Welded wire mesh also lacks flexibility, which means that it can only be utilized in one mode and cannot be used in several modes.

Application of mesh lace

The acronym BRC MESH is used to represent mesh, often known as engineering mesh. Engineers utilize this product for a wide range of purposes because of its great strength and variety. In truth, metal wire mesh is one of the strongest engineering constructions available.

This net is employed not just in the construction sector but also in the farming, petrochemical, and other sectors. Reinforcement in the foundation can be replaced by mesh nets. On the other hand, this product can be used to erect prefabricated concrete buildings with walls, roofs, and foundations.

Mesh nets can be used to fence factories, warehouses, and other structures since they come in a variety of sizes. Mesh can be used to create a fence and act as an obstacle to keep animals out of specified areas. Its additional applications include making composite roofing, channeling for subway roofs, building tunnels, water supply networks, and the bridge business.

This product will be utilized for a variety of projects, including the construction of stadiums, the flooring foundation for industrial halls, dams, sheds, and airport runways, among others. In practice, this product’s performance is not constrained to a small number of particular situations.

The advantages of using Welded Wire Mesh

- The building industry is the principal use for metal wire mesh. Metal meshes are employed to strengthen concrete since it has a relatively low tensile strength when subjected to applied forces.

- The geometric shape of the mesh contributes to its high network resistance. Construction processes are sped up by this feature.

- Fortunately, mesh nets are relatively inexpensive and efficient compared to other comparable items, and they can even contribute to project cost savings.

- Welded wire mesh netting’s excellent resistance to rust, corrosion, and ripping is one of its most significant benefits.

- Utilizing this product will optimize the usage of rebar and, in some cases, reduce the amount of rebar that is used.

- Buildings’ strength and durability will improve if mesh is employed to construct them.

- Mesh contributes to and complies with construction norms and principles.

- It is inexpensive and simple to transport.

Mesh lace price

Given the wide diversity of mesh nets and the many applications for which they are employed, it follows that varied pricing should be taken into account for the various models. What factors are used to establish this product’s pricing is the matter that arises. In answer, we must explain that the factors affecting the price are the thickness, kind of wire or rebar, size and shape of the apertures, and the texture of the mesh nets. Of course, characteristics like heat, rust, and corrosion resistance are also significant.

On the other hand, wire nets’ type of covering also has a substantial impact. Galvanized mesh net covers are more expensive than the other variants, but they are also available in black, stainless steel, and other colors. For 24 years, Afra SimTak Sadid Company has been in the business of manufacturing industrial and construction items, including galvanized wire, expanded metal, fences, gabion wire mesh, etc. The company delivers its commodities at competitive costs without compromising on quality.

Final word

Welded wire mesh is made from simple steel bars with ribs or from galvanized iron wires. The construction, agricultural, petrochemical, and other industries use this substance. Other applications for this net include foundations, canalization, tunnel construction, and fencing of various locations. Mesh nets are highly durable and resistant, and they also cost reasonably. Of course, the thickness, kind of wire or rebar, type of netting, and wire coating all affect the product’s cost.

Does welded wire mesh rust??

Architectural wire mesh is generally made from 316 stainless steel. This means that, standing alone, architectural mesh will not rust.