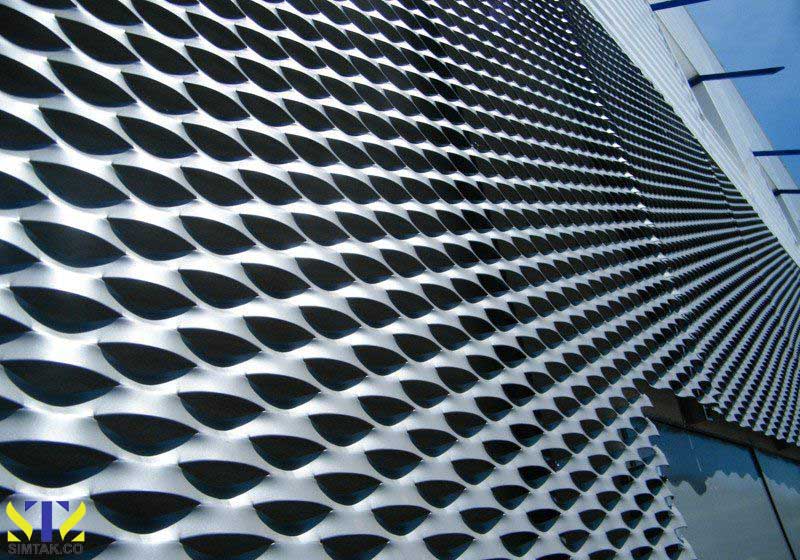

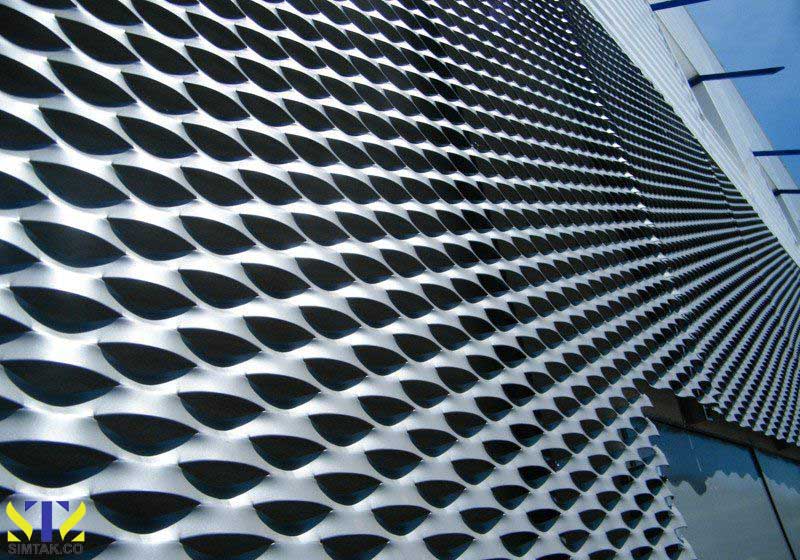

Expanded metals are metal mesh sheets. This sheet, of course, differs from a simple sheet of metal and has apertures of various sizes. There are various sorts of expanded metals, and their costs will change depending on a number of factors. The number of columns and the size of their apertures are two of the most significant variables that affect expanded metal prices. On the other hand, this sheet is made in the shapes of circles, squares, rhombuses, and other geometric shapes and has numerous uses. In Iran, expanded metals with apertures shaped like parallel sides are more frequently utilized.

What use do expanded metal serve?

Due to their wide variety and distinctive characteristics, expanded metals are utilized frequently. The majority of this sheet’s efficiency, however, is related to plastering the roof, clinging the facade, and retaining the mortar during masonry, which accounts for its significant consumption in the construction business. Using expanded metal banding wire, the expanded metals are attached to the rebar for this purpose, and plastering is then applied to them. In actuality, the reception and kitchen’s ceilings expanded metals are implemented using these steps.

expanded metals are also used to create iron cages. They are used to create cages because expanded metal are more resilient than any type of net, including chicken nets.

The sculpture industry makes use of this sheet as well. expanded metals are actually used by sculptors to create intricate, three-dimensional surfaces and complicated curves that are then covered in plaster, clay, or other materials.

Use the following link for watching & buying galvanized wire products from Sim Tak company: Galvanized wire

( Other products of Sim Tak: Fence netting )

Types of expanded metal

Construction materials typically come in a wide range, and even a single product may be split up into multiple groups based on a number of different criteria. expanded metals are also affected by this. This steel sheet is divided into weight, column, and spring categories. When you want to work with expanded metal in your building but are unsure of which kind to utilize, this issue becomes crucial. Certainly, learning about the various sorts of expanded metals and their individual traits will be helpful to you in these circumstances.

Expanded metal types according to a column

Different number of columns are created and provided for expanded metal depending on the type of use. Although 17-column expanded metals are more common outside of Iran, it uses 9, 11, and 13-column expanded metals more commonly in Iran.

13-column Plastering of ceilings and facades can be done with expanded metal. On the other hand, the 9-column model is occasionally used in place of the 13-column model in false ceilings, but this is non-standard and will cost more money. Because of this, it is preferable to seek advice from someone who has appropriate knowledge and experience in this area before selecting the breed of expanded metals.

Knowing that the price of expanded metal does not depend on the number of its columns is a beneficial thing. The price of expanded metal is actually determined by their weight and thickness; the quantity of columns has no bearing on this. Even in some instances, the extremely hefty 9-column expanded metal cost more since they weigh more than the lighter 11-column variety.

( Other products of Sim Tak: Gabion Wire Mesh )

Types of expanded metals based on weight

It is possible to use thin or thick sheets to create expanded metal. The weight of the expanded metal will be greater as the sheet’s thickness grows. In fact, expanded metal might be light, semi-heavy, heavy, or very heavy depending on the kind of sheet that is being utilized.

Despite the fact that heavy duty expanded metals are always more expensive, you shouldn’t always choose heavy duty types. For a false ceiling, for instance, flexibility is more crucial than expanded metal weight. Due to this, they employ light 9-column expanded metal rather than heavier ones. Typically, weight requirements are followed while purchasing and selling expanded metals, and their weight is monitored with a scale.

Types of expanded metal based on aperture

The openings between the columns of expanded metal are called fountains, and production expanded metal can be divided into two groups with two openings or three openings. The openings can be rhombus, squares, or parallelograms. In general, the greater the number of openings in expanded metal, the smaller their dimensions become.

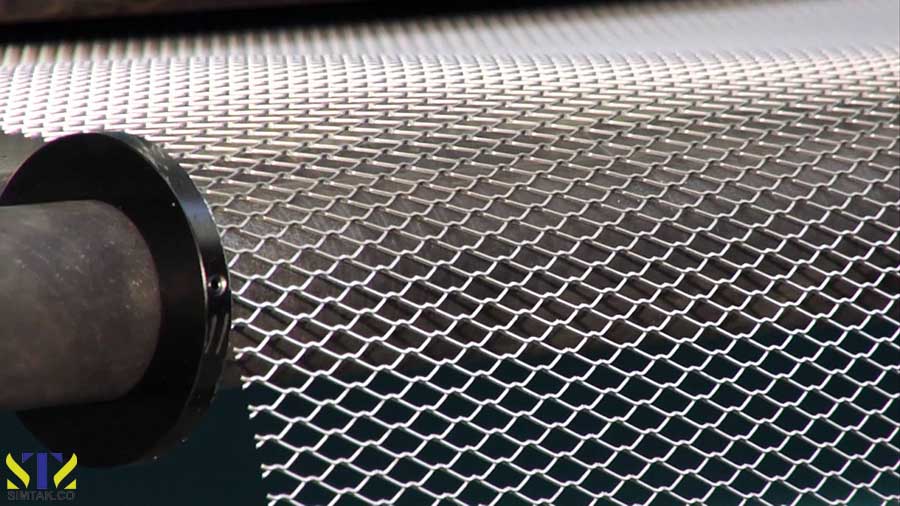

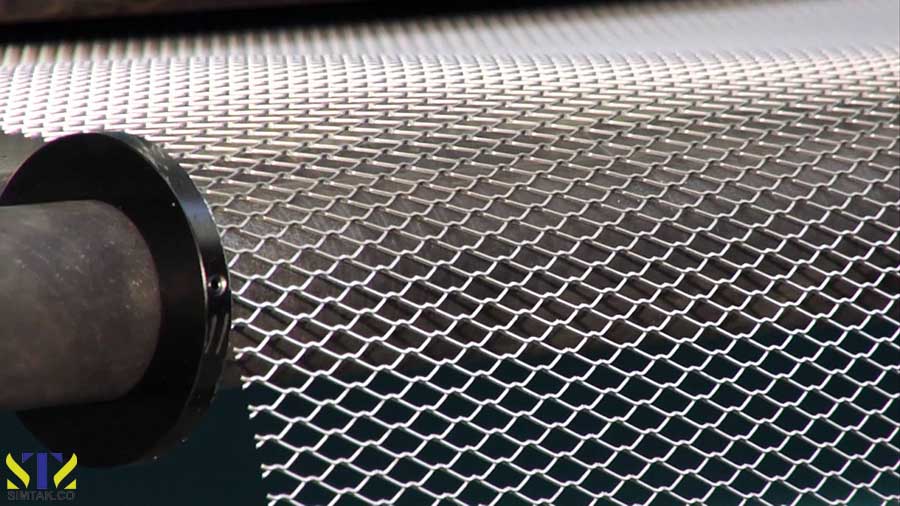

How to produce different types of expanded metal

Expanded metals are made using galvanized sheet as their base material. This product goes through two phases of slitting and transverse stretching during manufacture.

The galvanized sheet, which has a width of around 30 cm, is first put into the impact press machine used for slitting.

The sheet is then transversely stretched in this machine after slits are made on it by the mandrel.

At this point, expanded metal openings—which may be circular, square, etc.—are made.

The sheet is then stretched along its width using a roller in the following phase to widen it and leave a gap between the columns.

expanded metals are also provided in predetermined, uniform lengths and widths.

The weight of the expanded metal is used to calculate the final product’s price. In actuality, the final product’s price is decided by adding the predicted cost to the cost of the galvanized sheet.

Afra SimTak Sadid Group manufactures and exports hot galvanized wire, expanded metal wire, and other products, and it holds a sizable market share both domestically and abroad. To learn more, go to sim-tak.com.

( Other products of Sim Tak: Reinforcement wire )

Final word

Although there are several purposes for expanded metal, their primary function is in building. Among the uses of expanded metals are the construction of iron cages, the creation of intricate, three-dimensional surfaces in sculpture, plastering ceilings, cementing facades, and preserving mortar during stonework. Based on the number of columns, weight, and aperture, this product can be categorized. Furthermore, while some people believe that heavier expanded metals are more effective, this belief is incorrect, and the type of expanded metal you choose will depend on the purpose for which it will be used. Slitting and transverse stretching of the galvanized sheet are additional steps in the manufacturing of expanded metal. We guarantee the quality of our products at Afra SimTak Sadid Company since we have extensive experience producing all types of wire. As a result, you won’t need to worry about the product’s quality.

Recent posts:

What distinguishes hot galvanized wire from cold galvanized wire?

How to differentiate between hot and cold galvanized

What is #9 expanded metal?

Expanded metal #9,the most versatile and economical expanded metal mesh product, is made from the sheets or coils of mild steel, galvanized steel, stainless steel, aluminum, which are uniformly slit and stretched, forming a diamond pattern of openings in the finished sheet.